The difference between brass and copper, how to choose?

Release time: 27 Mar,2025

ID: 5

Views:

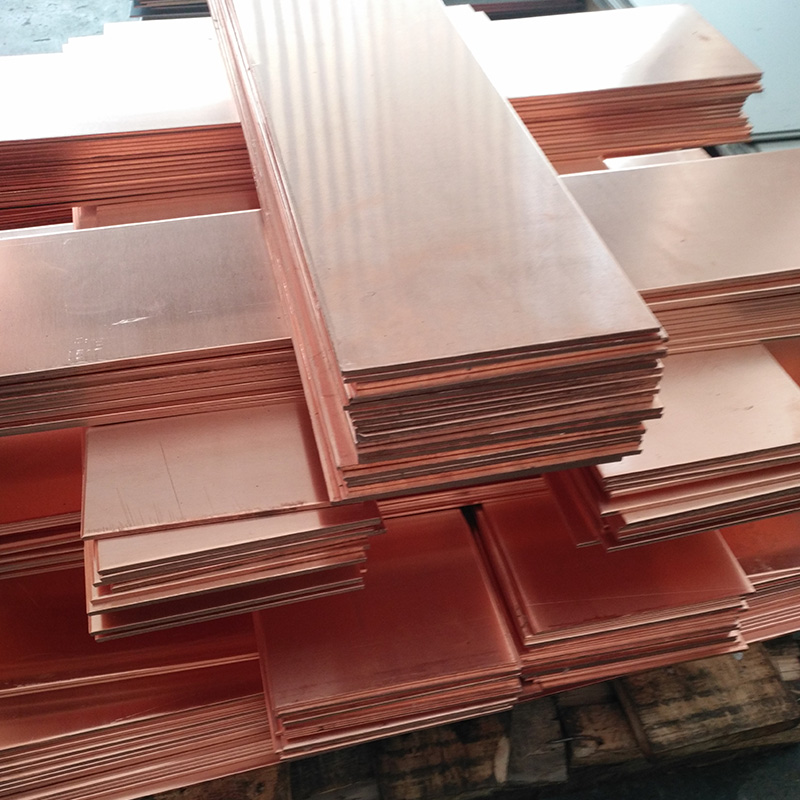

Brass and copper are two common copper alloys that differ significantly in composition, properties, and applications. The following are detailed comparison and selection suggestions:

First, core differences

Characteristics Copper (pure copper) Brass (copper-zinc alloy)

Composition copper content ≥99.9%, a small amount of impurities copper + zinc (zinc content 5%~45%), may contain lead, tin and so on

Color purplish red, dark gold after oxidation (lightens with increasing zinc content)

Excellent electrical and thermal conductivity (second only to silver), suitable for electrical use is poor, the higher the zinc content, the weaker the conductivity

Hardness/strength soft, good ductility, easy to bend higher hardness, wear resistance, excellent mechanical properties

Corrosion resistance resistance to atmospheric and water corrosion, but easy to vulcanize black corrosion resistance to seawater, adding tin, aluminum can improve the corrosion resistance

Machinability is easy to process, but the machinability is poor (sticky knife) cutting performance is good, suitable for precision parts processing

Higher cost (pure copper is more expensive) Lower cost (zinc is less expensive)

Second, how to choose?

1. Copper is preferred in the following scenarios:

Electrical/thermal conductivity requirements: such as wires, cables, transformers, radiators, etc.

High ductility requirements: parts that need deep stamping (such as copper POTS, artworks).

Diamagnetic environment: Copper is non-magnetic, suitable for precision instruments.

Food grade contact: Lead-free copper can be used in food processing equipment (subject to hygienic standards).

2. Preferred brass scene:

Mechanical performance requirements: such as gears, valves, locks, water pipe parts (H59, H62 and other brands).

Sea water corrosion resistance: Naval brass (e.g. HSn70-1 tin) for Marine fittings.

Low-cost processing: Screws and hardware (lead brass for easy cutting) that require mass production.

Decorative use: imitation of gold jewelry, Musical Instruments (such as saxophone brass containing 30% zinc).

Third, precautions

The zinc content of brass affects the properties:

Low zinc brass (such as H80) is closer to copper and has good ductility;

High zinc brass (such as H59) has high hardness, but is prone to "dezincification corrosion".

Environmental Protection and Health:

Leaded brass (such as HPb59-1) has good processing performance, but in contact with drinking water, choose a lead-free model (such as C69300).

Surface treatment:

Copper is easy to oxidize and needs to be protected by tinning or painting.

Brass can be polished to maintain its luster, or used (such as vintage hardware).

First, core differences

Characteristics Copper (pure copper) Brass (copper-zinc alloy)

Composition copper content ≥99.9%, a small amount of impurities copper + zinc (zinc content 5%~45%), may contain lead, tin and so on

Color purplish red, dark gold after oxidation (lightens with increasing zinc content)

Excellent electrical and thermal conductivity (second only to silver), suitable for electrical use is poor, the higher the zinc content, the weaker the conductivity

Hardness/strength soft, good ductility, easy to bend higher hardness, wear resistance, excellent mechanical properties

Corrosion resistance resistance to atmospheric and water corrosion, but easy to vulcanize black corrosion resistance to seawater, adding tin, aluminum can improve the corrosion resistance

Machinability is easy to process, but the machinability is poor (sticky knife) cutting performance is good, suitable for precision parts processing

Higher cost (pure copper is more expensive) Lower cost (zinc is less expensive)

Second, how to choose?

1. Copper is preferred in the following scenarios:

Electrical/thermal conductivity requirements: such as wires, cables, transformers, radiators, etc.

High ductility requirements: parts that need deep stamping (such as copper POTS, artworks).

Diamagnetic environment: Copper is non-magnetic, suitable for precision instruments.

Food grade contact: Lead-free copper can be used in food processing equipment (subject to hygienic standards).

2. Preferred brass scene:

Mechanical performance requirements: such as gears, valves, locks, water pipe parts (H59, H62 and other brands).

Sea water corrosion resistance: Naval brass (e.g. HSn70-1 tin) for Marine fittings.

Low-cost processing: Screws and hardware (lead brass for easy cutting) that require mass production.

Decorative use: imitation of gold jewelry, Musical Instruments (such as saxophone brass containing 30% zinc).

Third, precautions

The zinc content of brass affects the properties:

Low zinc brass (such as H80) is closer to copper and has good ductility;

High zinc brass (such as H59) has high hardness, but is prone to "dezincification corrosion".

Environmental Protection and Health:

Leaded brass (such as HPb59-1) has good processing performance, but in contact with drinking water, choose a lead-free model (such as C69300).

Surface treatment:

Copper is easy to oxidize and needs to be protected by tinning or painting.

Brass can be polished to maintain its luster, or used (such as vintage hardware).